Biodiesel 101

Well, I realized that there’s a lot of technical-jargon in my blog that makes things more complicated than they really are. So for anyone interested, here’s my best understanding of the biodiesel reaction process.

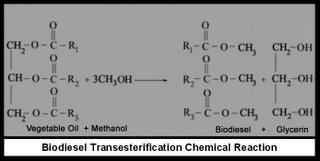

Any type of vegetable oil is composed primarily of triglycerides, which are essentially three really long carbon chains connected together by a glycerin backbone. This is very dense and thick, and will congeal when the temperature becomes too cold. Therefore, it doesn’t really work that well in diesel engines, especially when its cold outside. To compare, diesel fuel is one long chain of carbon. So biodiesel is essentially oil molecules that are chemically broken down to become similar to diesel molecules.

Here’s what happens in the biodiesel reaction. Methanol attacks the backbone of the oil and breaks it apart The backbone, glycerin, is very dense and falls to the bottom. The glycerin is then removed, and you’re left with biodiesel. Biodiesel is a long chain of carbon with a methyl ester on one side (a modified methanol). It’s pretty much the same density as diesel fuel, and although it does become solid at a higher temperature than diesel, it’s not a dramatically higher temperature. It’s safe to use in any diesel engine (as long as it’s older than the 1970’s). Biodiesel emissions are also much, much better for the environment. It can also be blended in any quantity with diesel fuel, in order to make a more cost effective, or winter safe fuel.

Simplifying slightly, a biodiesel reactor is pretty much a blender. You blend up clean, filtered, dry (no water) oil with methanol and KOH (a catalyst that speeds everything up). Heat, shake and stir, and you’ve got dirty biodiesel. Wait for things to settle, and then you drain the glycerin byproduct. Next, using water and air bubbles, you wash the biodiesel to remove all the nasty-non-biodiesel goodies. Finally, you again dewater the biodiesel, and you’re left with delicious biodiesel fuel that can be used in anything diesel. Simple as pie right?

<Credit must be given to this Iowa State webpage for their biodiesel reaction: http://www.me.iastate.edu/biodiesel/Pages/biodiesel3.html>

2 Comments:

At 5:17 AM, Anonymous said…

Anonymous said…

heh - first I want to say thanks - this is a first step to unjargonzing what you do! second, now I know what it feels like to be on the other end - i was slammed for this sharing about Dance Labs in a technical way yesterday at Plan. third, keeping going - there's still jargon left and really look forward to reading the "executive statement!" :)

At 3:57 PM, Anonymous said…

Anonymous said…

Dear Andy...

I am really enjoying reading your blog and I think you use a very easy jargon that is nicley understood also but not native EN speakers sich us the undersigned....myself that is.

Alter V.

I also sent an email to you please check it, in that I ask for information on your experiment and more.

I am an artist and I often happen to spend time in Thailand, to produce my work as well as to spend time with my thai friends and colleagues.

Hope to catch up with you soon....as my project on bodiesel must go on...

Best, Alter V.

Post a Comment

<< Home